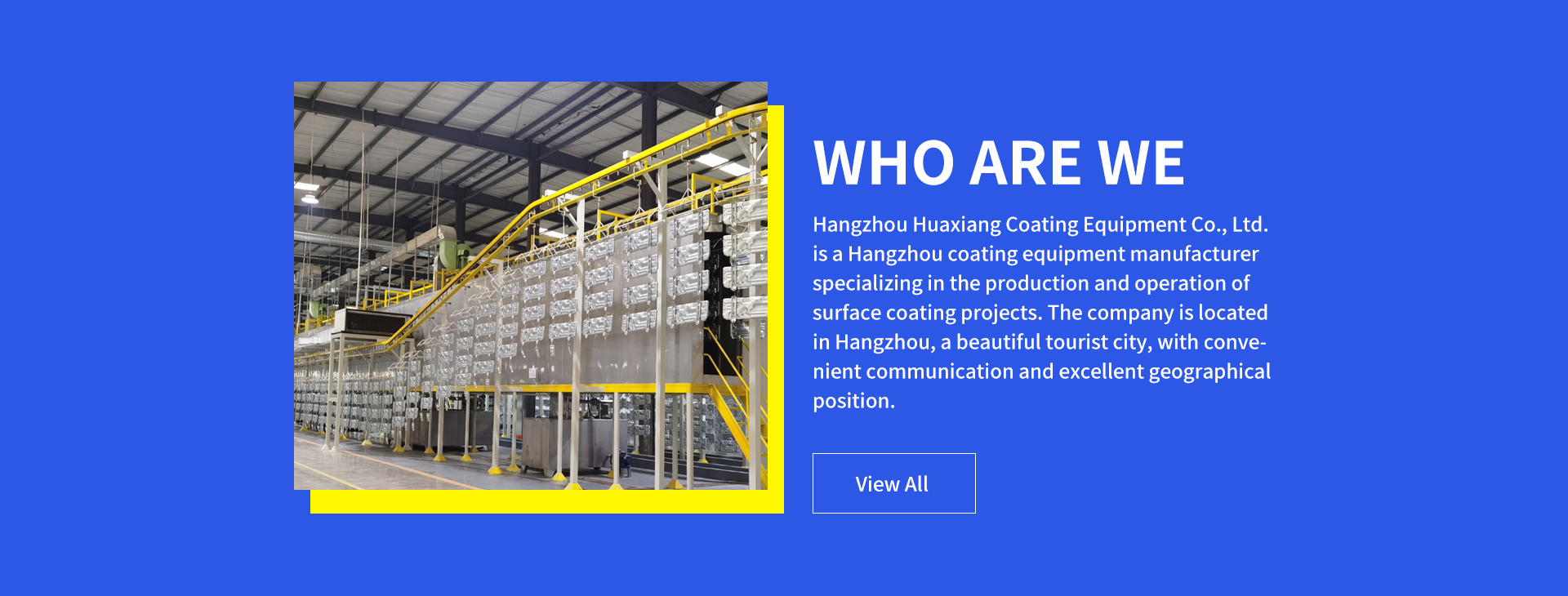

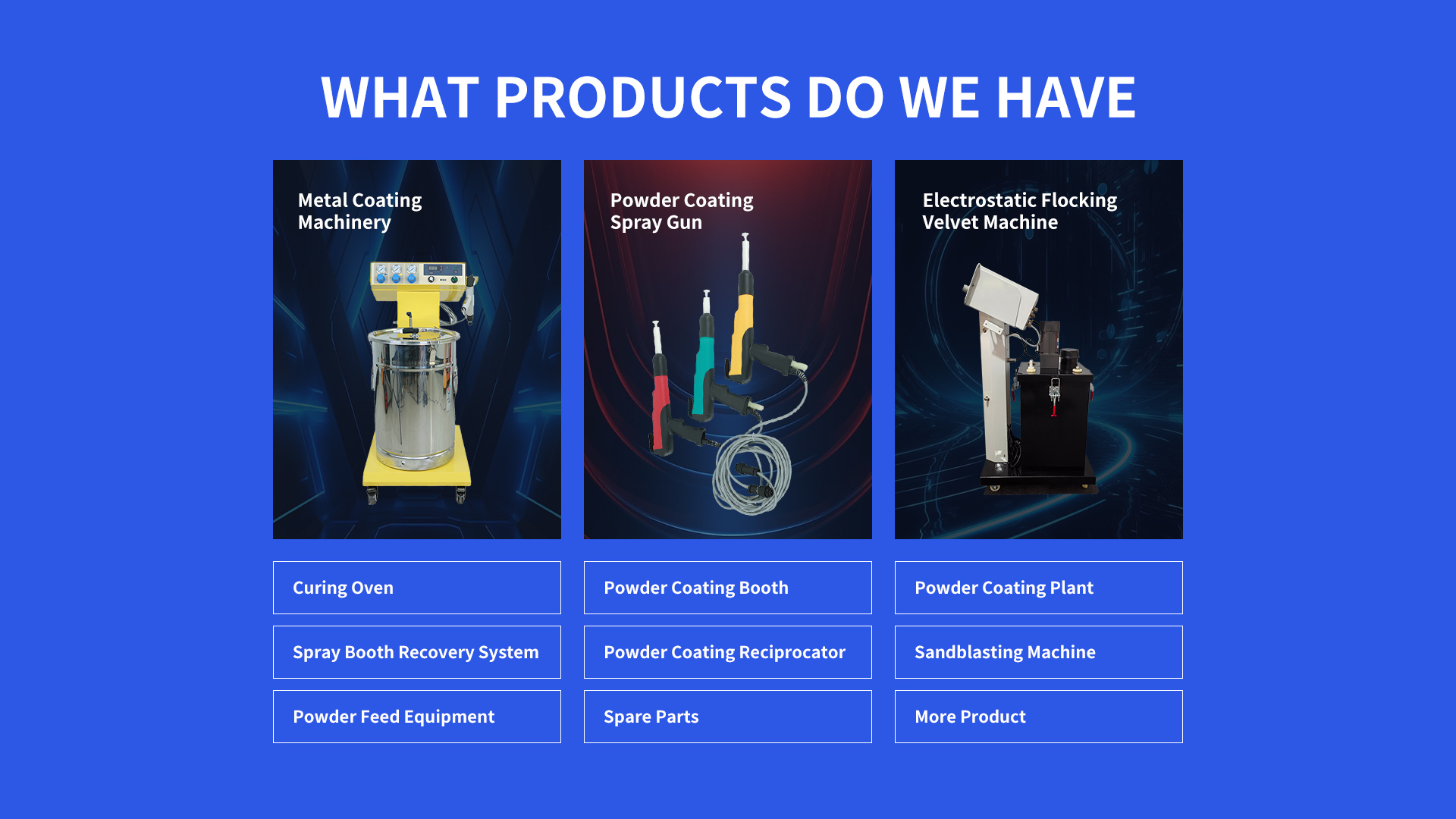

1. Intelligent Powder Coating Equipment Overview

Intelligent Powder Coating Equipment integrates advanced technologies like IoT, AI, and automation to optimize coating processes. Key components include smart spray guns with real-time feedback, AI-driven curing ovens, automated conveyor systems, and cloud-based monitoring platforms. These systems self-adjust parameters (voltage, airflow, temperature) for precision, reducing waste and enhancing efficiency in industrial settings.

2. Applications of Intelligent Powder Coating Equipment

Widely used in automotive, aerospace, electronics, and luxury goods manufacturing. Ideal for coating complex parts like EV battery casings, aircraft components, and consumer electronics. The technology excels in high-precision coating tasks requiring consistent quality, rapid production cycles, and minimal human intervention.

3. Pricing of Intelligent Powder Coating Systems

Costs range from 50,000forentry−levelIoT−enabledsystemsto500,000+ for fully autonomous lines with AI integration. Mid-range models (150,000–300,000) offer features like predictive maintenance and adaptive curing. Pricing reflects automation level, software capabilities, and smart coating technology scalability.

4. Proper Use of Intelligent Powder Coating Equipment

Input design specifications into the control software to enable AI-driven adjustments. Monitor real-time dashboards for parameters like powder flow and oven temperature. Perform routine calibration of sensors and AI algorithms. Clean self-diagnostic nozzles automatically via programmed cycles to ensure automated coating consistency.

5. How to Choose Intelligent Powder Coating Equipment

Prioritize systems with machine learning algorithms that adapt to part geometries. Ensure compatibility with Industry 4.0 infrastructure (e.g., ERP integration). Evaluate software updates and vendor support for AI-driven coating systems. Opt for modular designs to future-proof investments as production scales.

6. Safety for Intelligent Powder Coating Systems

Implement cybersecurity protocols to protect IoT-connected devices from breaches. Use automated emergency shutdowns triggered by AI anomaly detection. Operators must still wear PPE, as human oversight remains critical. Regularly audit smart curing oven safety logs and sensor accuracy.

7. Design Advantages of Intelligent Coating Equipment

AI algorithms optimize powder usage, reducing waste by up to 30%. Self-learning systems improve accuracy over time, minimizing rework. Cloud-based analytics provide insights into powder coating process efficiency, while energy-saving modes cut operational costs.

8. FAQs About Intelligent Powder Coating Equipment

Q: How does AI improve coating quality?

A: Machine learning analyzes historical data to refine predictive maintenance algorithms and coating parameters.

Q: Can these systems handle custom colors?

A: Yes, AI adjusts settings automatically for customized powder formulations.

Q: Are they compatible with legacy equipment?

A: Retrofit kits enable IoT upgrades for existing industrial coating lines.

Q: What is the ROI for intelligent systems?

A: Reduced waste and downtime typically yield ROI in 2–3 years for high-volume automotive coating.

Q: How secure is IoT data?

A: Advanced encryption and access controls protect smart powder application data.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com